Big Retail Fulfillment Models: Lessons For E-commerce Brands

Big Retail Fulfillment Models: Lessons For E-commerce Brands

Ever wonder how big retailers ship so fast without burning cash?

Trying to copy Amazon speed but on a Shopify budget?

Or stuck between outsourcing everything vs doing it in-house? 🤔

I’ve spent years watching how big retail handles fulfillment.

Here’s the distilled, practical take on Big Retail Fulfillment Models: Lessons For E-commerce Brands—what actually works, and what you can steal (without their budget).

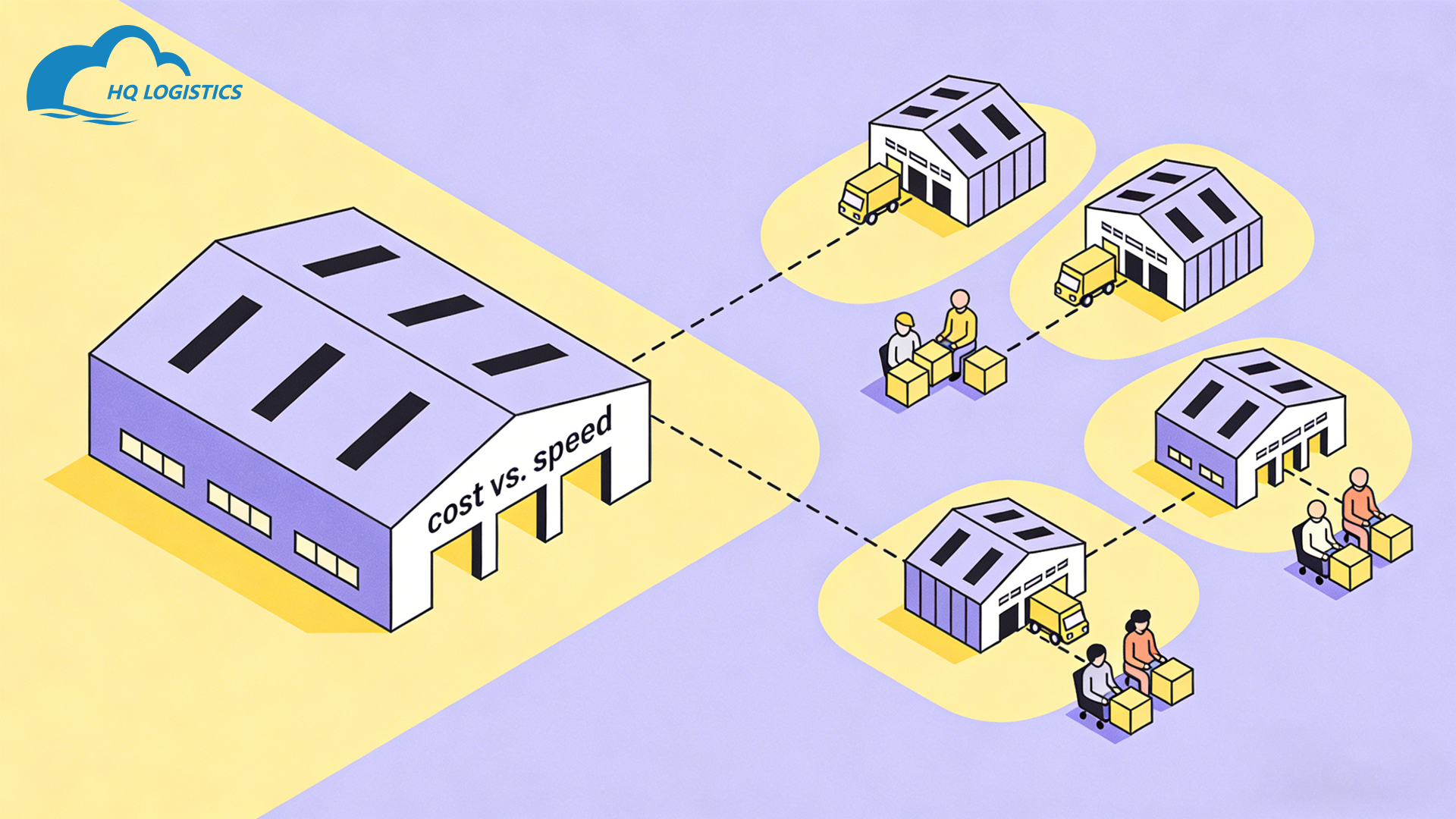

What “Big Retail Fulfillment Models” Really Mean

Big retailers don’t rely on one setup.

They run multiple fulfillment models at the same time.

Common ones:

-

Centralized distribution centers (DCs)

-

Regional warehouses

-

Store-based fulfillment

-

Third-party logistics (3PLs)

The key lesson?

Flexibility beats perfection.

Centralized Fulfillment: Control First, Speed Second

How big retail uses it

Most large brands start here:

-

One or two massive DCs

-

Inventory pooled in one place

-

Heavy automation 🤖

Why it works for them

-

Lower inventory duplication

-

Strong cost control

-

Easier forecasting

The downside (important)

-

Slower last-mile delivery

-

Higher shipping cost to distant customers

-

One disruption = big impact

Lesson for e-commerce brands

Centralized fulfillment is great when:

-

SKU count is high

-

Order volume is predictable

-

Speed is not your main selling point

Regional Fulfillment: Speed Wins Loyalty

What big retailers do differently

They place inventory closer to customers.

That means:

-

Multiple regional warehouses

-

Split inventory by demand

-

Faster delivery promises 🚀

Pros

-

Shorter delivery times

-

Lower last-mile cost

-

Higher conversion rates

Cons

-

More complex inventory management

-

Higher holding costs

-

Risk of regional stockouts

Lesson for smaller brands

You don’t need 10 warehouses.

Start with:

-

1 central location

-

1 regional 3PL for top markets

Speed where it matters most.

Store-Based Fulfillment: The Hidden Weapon

How big retail uses stores

Retail stores double as:

-

Mini fulfillment centers

-

Local pickup points

-

Return hubs

This enables:

-

Same-day or next-day delivery

-

Lower return shipping cost

Why it’s powerful

-

Inventory already paid for

-

Close to customers

-

Flexible during peaks

Reality check for DTC brands

Most e-commerce brands don’t have stores.

But the principle still applies.

What you can copy

-

Micro-fulfillment via local 3PLs

-

Urban warehouses for fast SKUs

-

Returns routed to the nearest location

3PL-Led Fulfillment: Scale Without Owning Everything

Why big retailers still use 3PLs

Even giants outsource when:

-

Entering new regions

-

Testing new categories

-

Handling peak season overflow

Benefits

-

Fast scalability

-

Local expertise

-

Less upfront investment

Risks

-

Less direct control

-

Variable service quality

-

Pricing can creep up over time

Lesson for growing brands

Use 3PLs as:

-

A growth lever, not a crutch

-

A test before committing long-term

A Short Real Example ☕

I once worked with a brand obsessed with copying Amazon.

They tried:

-

Nationwide fast shipping

-

One warehouse

-

No 3PL support

Result?

High shipping costs.

Late deliveries.

Burned margins.

We switched to:

-

Central warehouse for most orders

-

Regional 3PL for top 2 states

Delivery got faster.

Costs went down.

Customers noticed.

Big retail thinking—scaled down.

What Big Retail Does Better Than Most DTC Brands

Here’s the real difference.

Big retailers:

-

Plan 12–18 months ahead

-

Build redundancy into fulfillment

-

Assume disruption will happen

They don’t ask:

“Will this break?”

They ask:

“When it breaks, what’s Plan B?”

Practical Fulfillment Lessons You Can Apply Now

Steal these ideas:

-

Segment SKUs

-

Fast movers vs long tail

-

-

Segment customers

-

Speed-sensitive vs price-sensitive

-

-

Split fulfillment

-

Not everything ships the same way

-

Simple framework I like:

-

70% efficiency

-

20% speed

-

10% flexibility buffer

That buffer saves brands every peak season.

FAQs: Big Retail Fulfillment Models

1. Do I need multiple warehouses to compete?

No. You need the right warehouse setup, not more buildings.

2. Is fast shipping always worth it?

Only if it increases conversion or retention.

3. Should small brands copy Amazon’s model?

No. Copy the logic, not the scale.

4. When should I add a 3PL?

When growth outpaces your current setup—or before peak season.

5. How do big retailers handle returns so well?

They route returns locally and reuse inventory fast.

Final Take

Big retailers win at fulfillment because they design for reality, not perfection.

You don’t need their budget.

You need their mindset:

-

Flexibility

-

Redundancy

-

Smart trade-offs