Q1 Fulfillment & Dropshipping Strategy: How to Save on Shipping and Scale Faster

Q1 Fulfillment & Dropshipping Strategy: How to Save on Shipping and Scale Faster

New year, new targets.

But Q1 fulfillment can quietly slow everything down.

After Chinese New Year, operations restart unevenly.

Inventory, logistics, and demand all move at different speeds.

If you don’t plan your Q1 fulfillment and dropshipping strategy,

you risk delays, higher costs, and lost momentum.

Let’s break down how brands handle Q1 fulfillment without rushing or overspending.

Why Q1 Fulfillment Is a Critical Reset Period

Q1 is not just another quarter.

It sits between:

-

Post–holiday demand correction

-

Chinese New Year recovery

-

Inventory rebalancing

-

New product testing

What happens in Q1 sets the tone for:

-

Shipping stability

-

Cost structure

-

Scaling readiness

Strong fulfillment in Q1 is about control, not speed.

Q1 Fulfillment Challenge #1: Post–Chinese New Year Recovery

Operations don’t fully normalize right after Chinese New Year.

Common issues include:

-

Factory ramp-up delays

-

Warehouse labor gaps

-

Logistics backlog

-

Inconsistent transit times

Best practice:

-

Avoid aggressive delivery promises in early Q1

-

Build buffer inventory

-

Work with fulfillment partners who plan capacity early

This reduces risk while operations stabilize.

Q1 Fulfillment Challenge #2: Inventory Rebalancing

Q1 is when inventory mistakes surface.

Typical situations:

-

Overstock from Q4 promotions

-

Fast-selling SKUs running low

-

New products entering inventory

Smart Q1 fulfillment focuses on:

-

SKU-level demand forecasting

-

Clearing slow-moving inventory

-

Preparing winning SKUs for scale

Inventory clarity keeps cash flow healthy.

Q1 Fulfillment Challenge #3: Logistics Cost Volatility

Shipping costs don’t settle immediately in Q1.

You may see:

-

Rate adjustments after peak season

-

Priority line availability changes

-

Carrier capacity shifts

Brands that manage this well:

-

Lock stable logistics routes early

-

Use multiple shipping channels

-

Avoid last-minute routing decisions

Cost predictability matters more than speed in early Q1.

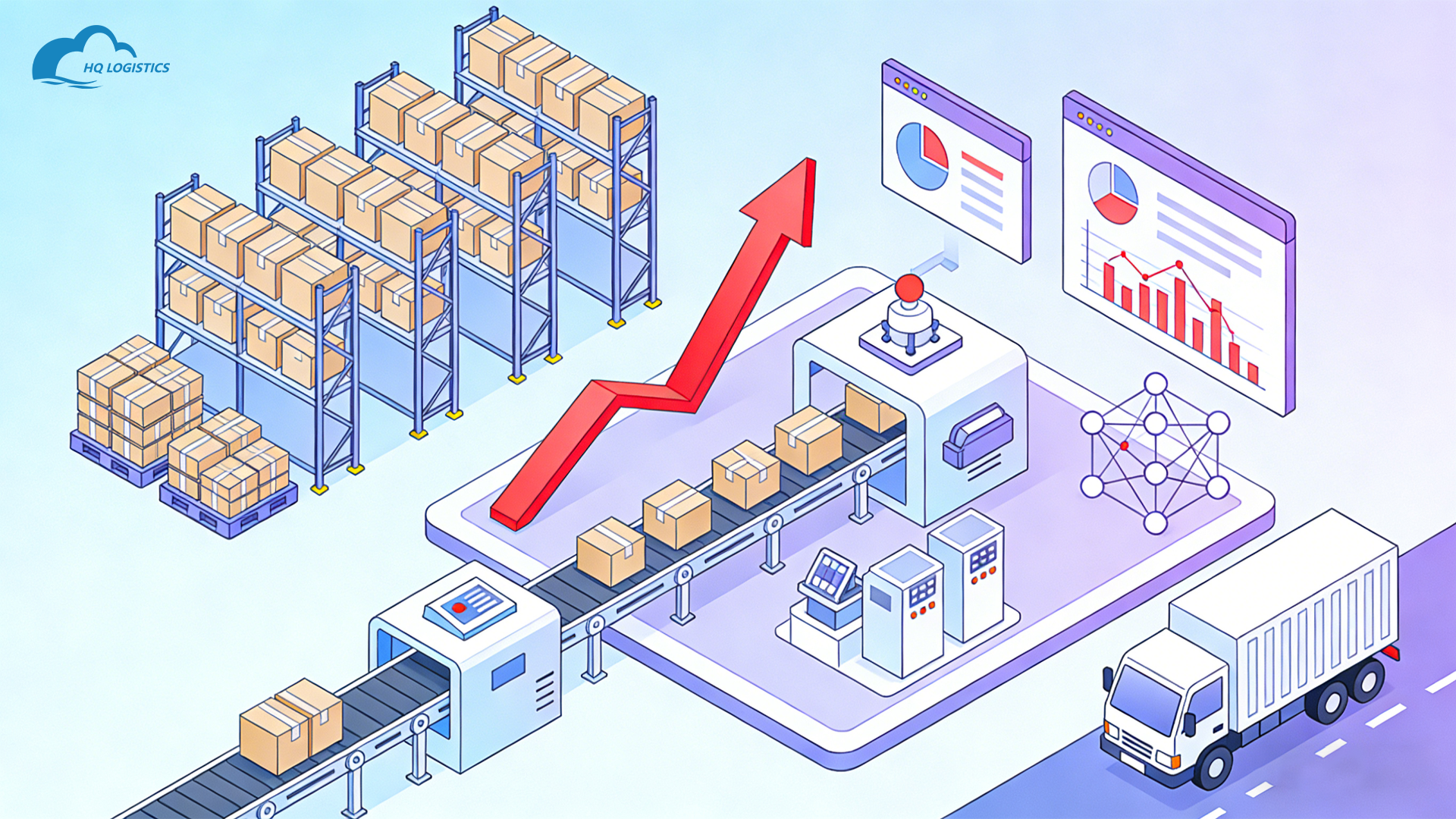

Fulfillment Models That Work Best in Q1

Your fulfillment model determines flexibility.

Dropshipping in Q1

Best for:

-

Testing new SKUs

-

Managing uncertainty

-

Reducing inventory risk

Limitations:

-

Higher per-order cost

-

Less control during recovery periods

Bulk Fulfillment in Q1

Better for:

-

Stable demand

-

Faster delivery

-

Long-term cost efficiency

Many brands start Q1 with dropshipping

and gradually shift winning products into bulk fulfillment.

Why Q1 Is the Best Time for Dropshipping Cost Advantages

Q1 is one of the few periods where dropshipping costs are more flexible.

After peak season ends and operations restart post–Chinese New Year,

many fulfillment providers and logistics channels adjust pricing to stabilize volume.

This creates opportunities for:

-

Lower per-order fulfillment costs

-

More flexible dropshipping rates

-

Better access to stable logistics lines

-

Faster onboarding for new SKUs

For brands testing products or rebuilding momentum after Q4,

Q1 dropshipping offers a cost-efficient way to stay active without heavy inventory pressure.

How Smart Brands Use Q1 Dropshipping Advantages

The goal in Q1 isn’t aggressive scaling.

It’s efficient experimentation.

Experienced sellers often:

-

Test new products via dropshipping instead of bulk stocking

-

Use Q1 cost advantages to protect margins

-

Keep ads running without large inventory commitments

-

Transition only proven SKUs into bulk fulfillment

This approach limits downside

while preparing for growth later in the year.

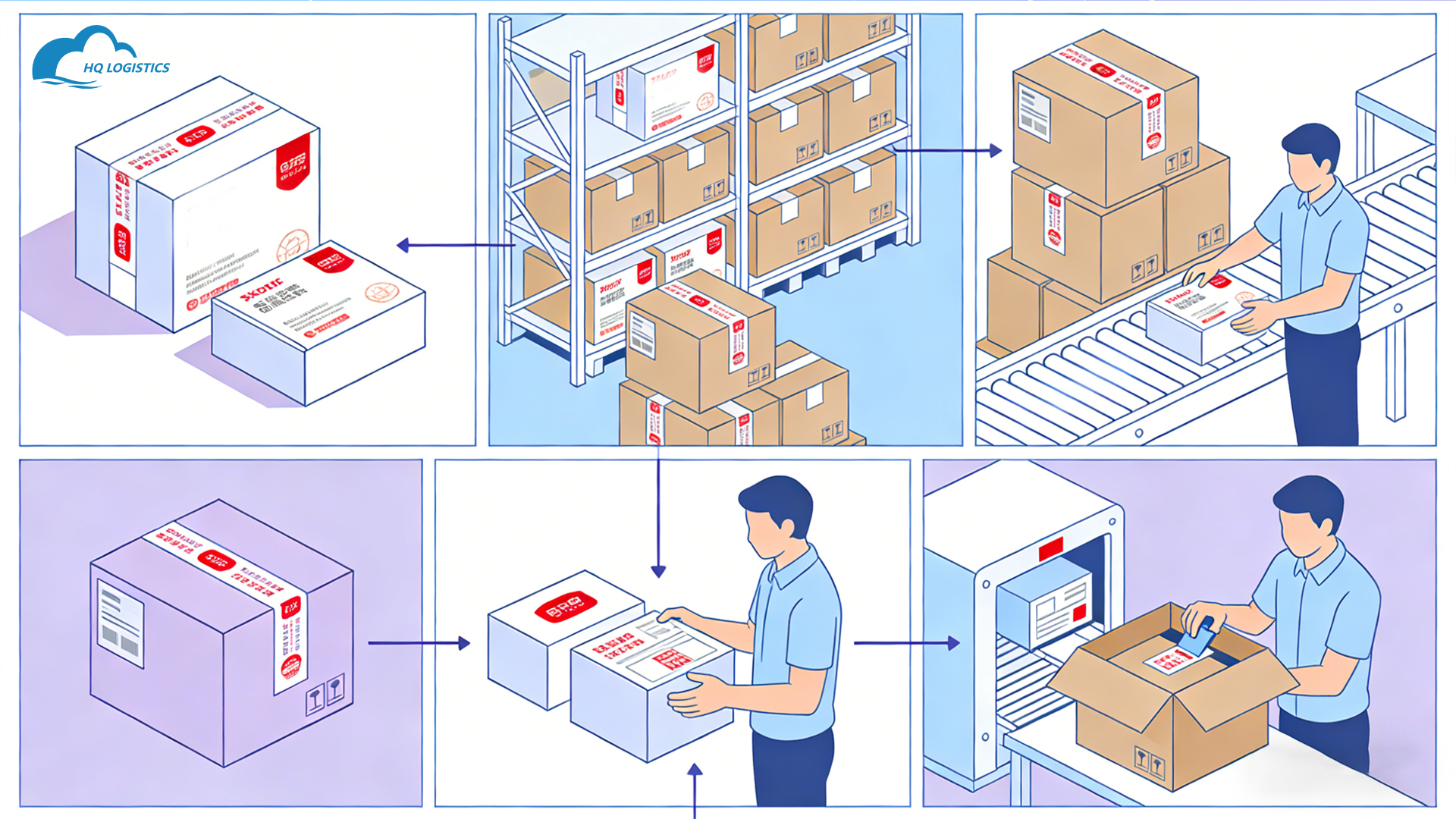

Packaging & Branding Opportunities in Q1

Q1 is a reset moment.

It’s an ideal time to:

-

Refresh packaging designs

-

Improve protection and materials

-

Optimize packaging costs

-

Prepare branding updates for upcoming campaigns

Making these changes early avoids disruption in peak seasons.

A Real Example From the Field

One brand scaled ads aggressively in early Q1.

Sales increased.

Fulfillment struggled.

Why?

-

Inventory wasn’t fully restocked after Chinese New Year

-

Logistics routes weren’t secured

-

Dropshipping costs weren’t reviewed

Result:

-

Shipping delays

-

Refund requests

-

Lost momentum

Q1 rewards preparation — not optimism.

How HQ CLOUD Supports Q1 Fulfillment & Dropshipping

At HQ CLOUD, we treat Q1 as a stabilization and optimization phase.

Our Q1 support includes:

-

Inventory planning and SKU review

-

Post–Chinese New Year ramp-up coordination

-

Flexible dropshipping fulfillment options

-

Optimized logistics routes

-

Smooth transition from dropshipping to bulk fulfillment

-

Custom packaging readiness

This helps brands reduce costs while preparing to scale.

FAQs From Real Sellers

Is Q1 a good time to test new products?

Yes. Q1 is ideal for low-risk testing via dropshipping.

Are shipping times slower in Q1?

Early Q1 can be inconsistent, especially after Chinese New Year.

Should I rely only on dropshipping in Q1?

Not always. Use dropshipping first, then shift winning SKUs to bulk fulfillment.

Does Q1 offer better fulfillment costs?

Often yes, due to post-peak adjustments and capacity availability.

Final Thought

Q1 isn’t about moving fast.

It’s about setting the foundation.

A strong Q1 fulfillment and dropshipping strategy gives you:

-

Predictable shipping

-

Controlled costs

-

Inventory clarity

-

Room to scale confidently in Q2 and beyond

Start Q1 with intention —

and the rest of the year becomes easier.